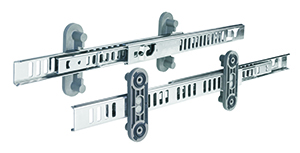

Smooth running with added value. New stainless steel telescopic slide for dishwashers.

Schock Metall has been known for innovative pull-out technology for many years. Last but not least, in 2015, by picking up the "Best of the Best" interzum award for its "AIR MOTION" smooth running guides, the German roll form specialist proved its competence in the field of high-precision forming technology. A current example of how new ideas succeed in the market can currently be seen in the field of application 'white goods'. More than 15 years ago, the Urbach-based company developed the first "CleanSlide" ball bearing guide for the upper basket in the dishwasher and has been supplying it to renowned manufacturers of premium appliances ever since. At the IFA 2014, the first appliance that was affordable for the general public was presented with telescopic rails on three levels. Since then, this market has been booming and many manufacturers of appliances have followed suit with smooth running, laterally stable self-cleaning dishwasher pull-outs from Schock.

Schock developed a new stainless steel telescopic rail for a large, international manufacturer of dishwashers. According to Thomas Kirn, Head of Sales and authorised representative at Schock Metall, the experience which has been gained with the pull-outs which have been used so far, as well as innovative ideas, was decisive for being assigned the project: Due to several weak points, the competitive product led to significant failures in the field. The customer needed a supplier which was able to introduce new solutions to the device in terms of running quality and connectivity strategy, as well as design the development process through to serial production in the time required by the market.

The new telescopic rail is based on the technologies developed by Schock "CleanSlide" and "Air Motion". The first technology stands for patented self-cleaning with holes punched through in the rail profiles. The second technology describes extremely light and smooth running with extremely reduced basket correction forces. The latter are crucial to the optimum return of the guides when inserting the baskets into the device. After all, the door can only be fully and securely closed when they are fully inserted.

The 2K plastic holders for connection to the side wall in the dishwasher are also new. The sealing elements are non-detachable and integrated into the plastic holder. As a result, the seals cannot fall out during transport. This means zero-error production in the assembly and zero-leakage operation in terms of the application. The suspension system for mounting the baskets was also developed through co-engineering with the customer. The interfaces provided for this purpose are formed using the punching technique used by Schock simultaneously with the feed-through holes in the roll forming process. In order to eliminate the risk of injury to the user, the virtually burr-free profiles of the extending inner rail are additionally machined at the front end. Depending on the customer's needs, Schock Metall uses a variety of different processes, from embossing and brushing through to mechanical protection using attached plastic parts.

All components used in household appliances are food-safe and have the appropriate approvals for the European as well as for the American market. Depending on customer requirements regarding protection against corrosion and optics, Schock Metall uses various stainless steels as well as hot-dip galvanised steels, with or without additional surface refinement. As well as an engineering partner for its customers, Schock Metall not only sees itself as a source of ideas in this sector, but also in its other areas of business, living, automotive and industry: As Thomas Kirn explains, "With us, every customer gets their own individual guidance system". "Here, the key elements are the jointly defined connection strategy and integrated convenience functions. Within the scope of the project, the configuration of the running properties through to noise generation is certainly one of our unique selling points".

The basis for these high-quality characteristics is the applied production technology of roll forming. Schock has developed this forming process as a core competence, with extremely narrow tolerances and a variety of integrated processes.

For pricing and availability please contact our sales team on 01623 655 265 or email us on sales@sdproducts.co.uk.